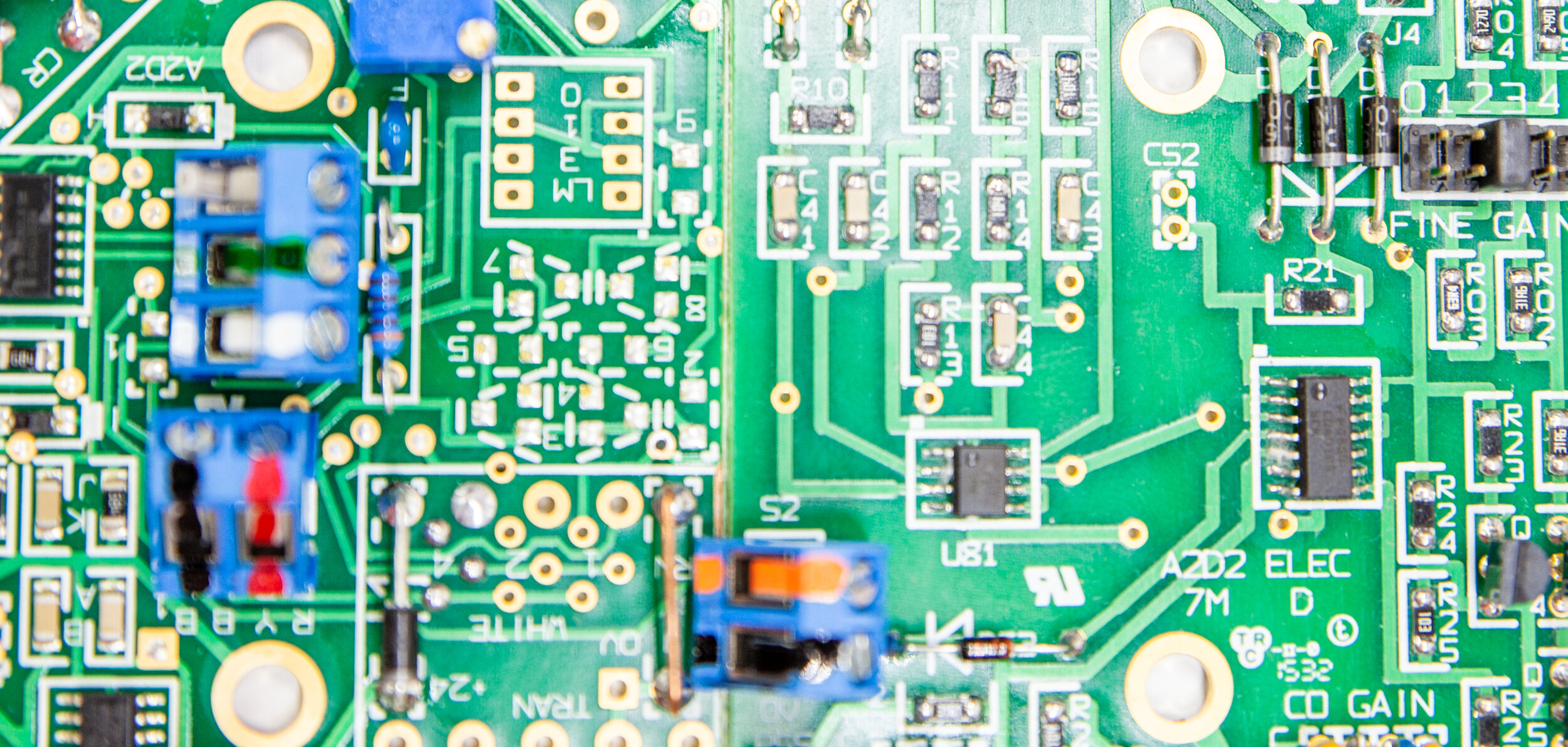

A2D2 Electronics

(612) 889-0946 | don@a2d2.com

Industrial Real-time Processing Sensors for Moisture & Bin Level.

Reducing operational costs, improving quality control, and ensuring product value.

Contact Us

Feel free to contact us with any questions.

Email

don@a2d2.com

gayle@a2d2.com

Phone

Don: (612) 889-0946

Gayle: (218) 260-9663